One of the most critical factors for success is how you organize and store your items. With the right industrial racking system, you can maximize your storage space, reduce clutter, and improve the overall efficiency of your operations. But what exactly is an industrial racking system, and how can it help optimize your storage?

In this article, we’ll explore the many benefits of industrial racking systems, how they work, and how they can help you make the most of your available space.

What is an Industrial Racking System?

The Basics of Industrial Racking Systems

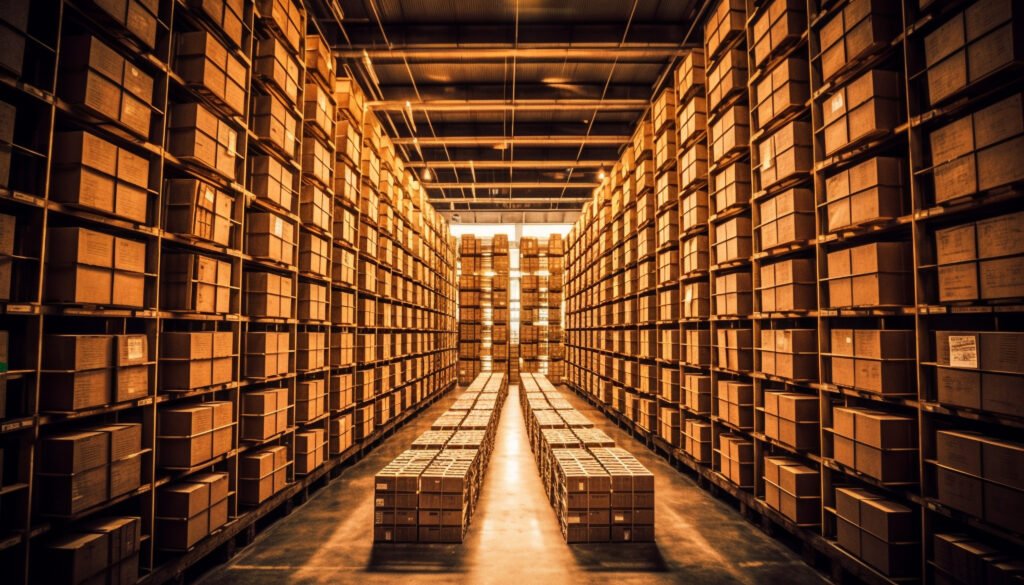

An industrial racking system refers to a storage solution designed for the efficient storage of large quantities of goods, equipment, or materials. These racking systems are typically used in warehouses, factories, and distribution centers to store inventory in a structured and organized way. The system includes various types of shelves, beams, and supports that hold items off the ground and create space for more products.

Industrial racking systems are versatile and come in a wide range of designs, sizes, and materials to meet different storage needs. Whether you need to store palletized goods, bulk items, or smaller parts, there’s a racking solution that fits.

Note:- Looking for reliable industrial racking system in UAE? Get in touch with Stormat Systems for high-quality, durable racking solutions tailored to your business needs. The expert team will help you optimize storage, improve efficiency, and maximize space in your warehouse or facility. Contact today to learn more about our industrial racking systems and how we can support your business!

Types of Industrial Racking Systems

There are several types of racking systems available, each designed for specific storage needs. Some of the most common types include:

- Pallet Racking: Ideal for storing large quantities of goods on pallets, this system helps to keep everything organized and accessible.

- Cantilever Racking: Best for storing long or bulky items, such as pipes or lumber.

- Drive-In Racking: A high-density storage option where forklifts can drive into the racking system to retrieve or store goods.

- Push-Back Racking: Allows for the efficient storage of pallets, utilizing a system where the goods are pushed back on rails for easy retrieval.

- Selective Racking: A flexible racking system where each item can be individually accessed without moving other pallets.

Each of these racking systems can be tailored to fit your unique storage requirements, maximizing the available space.

Why is Space Maximization Important for Industrial Storage?

Space Optimization Leads to Efficiency

In any warehouse or industrial setting, space is a valuable resource. The more efficiently you can use your space, the more products you can store, and the less cluttered your facility will feel. By optimizing your storage space, you can improve operational efficiency and reduce costs.

Properly utilizing storage space also means you’ll spend less time searching for items, reducing the likelihood of errors and delays. This can help improve order fulfillment, boost productivity, and streamline your business operations.

Cost Savings

A well-organized warehouse means fewer storage costs. For instance, if you can fit more items into the same square footage, you won’t need to invest in additional space, which can save you money on rent, utilities, and maintenance. Furthermore, industrial racking systems reduce the need for inefficient storage solutions like stacking items on the floor, reducing the risk of damage and improving inventory management.

Maximizing Floor Space

An efficient racking system not only utilizes the available vertical space but also helps you make the most of your floor area. By stacking items on shelves, beams, or racks, you free up floor space that can be used for other essential activities like staging shipments, receiving goods, or allowing for easy movement within the facility.

How Can an Industrial Racking System Maximize Your Storage Space?

1. Utilizing Vertical Space

One of the best ways to maximize storage in any warehouse or industrial setting is to use vertical space. Most industrial racking systems are designed to take full advantage of the height of your facility, stacking goods and products several levels high. Instead of only using the floor area for storage, you can store items from floor to ceiling, which significantly increases your storage capacity.

For example, pallet racking systems can often be stacked as high as your ceiling allows, depending on the height of your warehouse. By going vertical, you can store large quantities of goods in a smaller footprint, leaving more room for other operations.

2. Maximizing Storage Density with High-Density Racking

High-density racking systems are designed to maximize the amount of product you can store in a small area. These systems often use innovative designs like drive-in racking or push-back racking, where goods are stored in rows and accessed from one or both ends.

By storing goods in high-density racks, you can fit more products into the same amount of space, reducing the need for extra storage areas. These types of systems are ideal for warehouses that have high turnover rates or large volumes of inventory.

3. Organizing by Size and Weight

With an industrial racking system, you can organize your products based on their size and weight. Heavier items can be placed on lower shelves for easy access, while lighter items can be stored higher up. This not only maximizes space but also improves workflow by reducing the time it takes to retrieve products.

By grouping similar items together and organizing them by size, weight, and frequency of use, you create a more efficient storage system. This organization helps you reduce clutter and make the most of the space available.

4. Reducing Aisle Space

With traditional shelving or storage systems, you may need wide aisles to allow for forklifts or personnel to move products around. However, an industrial racking system can help reduce the width of aisles while maintaining safety and accessibility. Narrow aisles or very narrow aisle (VNA) systems allow you to fit more racking in the same area, making the most of every inch of your warehouse.

By using specialized equipment like narrow aisle forklifts, you can create more compact aisles that maximize storage without sacrificing functionality or safety.

5. Flexible Storage Options

Industrial racking systems offer flexibility in design, meaning you can adjust your layout as your needs change. If your business grows and you need more storage space, you can simply add more racks or adjust the existing ones to accommodate new inventory. Unlike static storage solutions, industrial racks can be reconfigured to meet your changing requirements.

This flexibility ensures that your storage system can adapt to the ever-changing nature of business operations, whether you need to store seasonal goods or adjust for different product sizes.

6. Improving Accessibility and Efficiency

While maximizing storage is essential, you also want to ensure that your goods are easily accessible. An efficient racking system makes it simple to locate, retrieve, and restock items. By organizing your inventory based on product types, you reduce the amount of time spent searching for products and improve order fulfillment speeds.

Racking systems such as selective racking allow you to access any item without moving others, making it easier to manage inventory and prevent bottlenecks. This accessibility increases efficiency and can contribute to faster turnaround times in your warehouse or distribution center.

How Do You Choose the Right Racking System?

1. Assess Your Storage Needs

Before selecting an industrial racking system, you need to assess your specific storage needs. Consider factors like the type of products you store, their weight, size, and how often they are accessed. You also need to think about how much space you have available and your budget for installation.

2. Optimize for Workflow

Your racking system should also be designed with workflow in mind. Think about how products will be received, stored, and dispatched. An efficient racking system should streamline these processes, making it easy to manage inventory and reduce errors.

3. Consult with Experts

Selecting the right racking system for your needs can be complex, especially when you’re dealing with large volumes of inventory or specialized products. It’s important to consult with storage experts who can help you design a racking system tailored to your space and operational requirements.

Conclusion

An industrial racking system is a game-changer when it comes to maximizing your storage space. Whether you are looking to improve space efficiency, increase inventory accessibility, or optimize workflow, the right racking solution can make a big difference. By utilizing vertical space, organizing based on product types, and incorporating flexible storage options, you can make the most of your available storage area and improve overall operational efficiency.

Investing in a well-designed racking system is not only a smart move for today’s needs but also a long-term solution that can grow with your business. So, whether you are running a small warehouse or a large industrial facility, choosing the right racking system will help you make the most of every inch of space.

Note:- To read more articles visit on bipamerica.